Model No.: JHFC

Brand: QuanJinHe

Place Of Origin: China

Status: New

Processing Type: Foaming Machine

Product Category: Laminated Tube, Bubble Film, Fast Food Box, Foam Net, Pe Film, Pet Strap, Plastic Bag, Plastic Bottle, Plastic Cup, Plastic Pipe, Plastic Rope, Plastic Sheet, Pp Woven Bag, Pvc Profile

Certification: Ce, Ul

Warranty Period: 1 Year

Core Selling Point: Automatic, Multifunctional, Competitive Price, High-Accuracy, High Safety Level, Energy Saving, Sustainable, Long Service Life, High Productivity, Easy To Operate, Flexible Manufacturing

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Applicable Industry: Building Material Shops, Manufacturing Plant, Retail, Construction Works

Marketing Type: Ordinary Product

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Bearing, Motor, Pump, Gear, Plc, Other, Pressure Vessel, Engine, Gearbox

Voltage: Customized

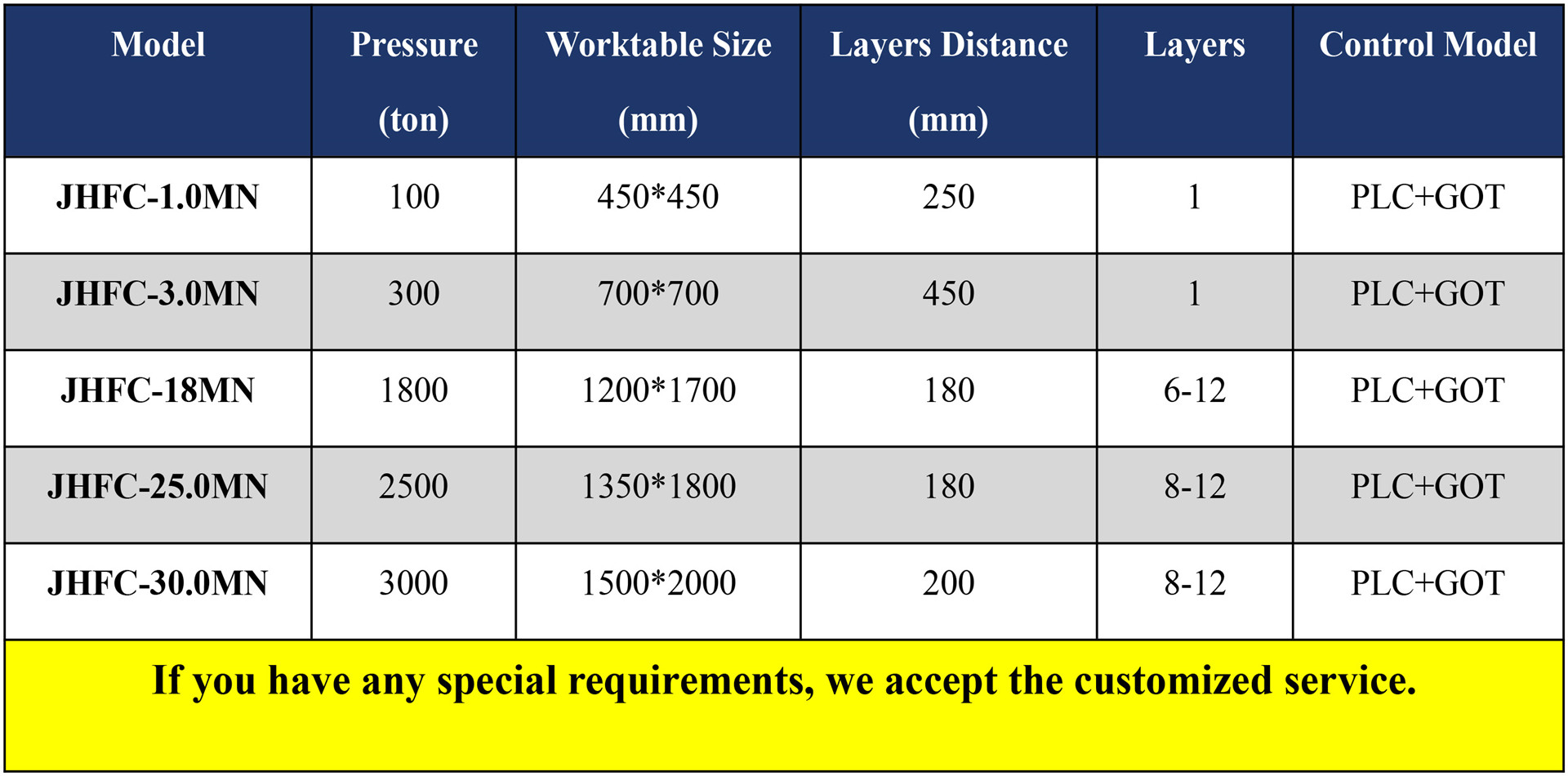

Pressure: 1800 ton

Layers: 6-12 layers

Layer Distance: 180 mm

Control Mode: PLC+GOT

Application: Aerospace, rail transit, automobiles, surface vessels, wind turbineblades, buffer packaging, cold chain logistics, sports protection,biomedicine, etc.

Foaming Agent: CO2; N2

Frequency: Customized

Working Table: 1200x1700 mm, Customized

Product Name: PE Supercritical Foaming Molding Machine